TREATMENTS WITH GEMS: HOW THE STONES ARE "IMPROVED".

Already at the birth of Christ it was realized that the quantity of "beautiful" gems was not sufficient to satisfy the global demand of the time. Then the "treatments" begin: rubies and sapphires are "cooked" to optimize color and clarity, emeralds are put in oil (cedar) to hide the cracks.

Since then, attempts to artificially increase the value of gemstones have become more extravagant and sophisticated. On the other hand, laboratory studies have evolved and it is possible to discover all the treatments that always reduce the value. Precisely for this reason, a certificate from an internationally recognized gemstone laboratory is essential when buying a gem.

With all gemstones, a distinction must be made between treatments that are permanent and difficult to reverse (examples are heating the sapphire or filling the crack with lead glass for the ruby) and those that are temporary and also reversible (e.g." to the Emerald).

Gem cutting is not considered a treatment. Naturally colored and untreated gemstones are only those whose color or clarity has not been artificially altered.

There are also synthetic stones, which are artificial products made by man in the laboratory, which have chemical and physical properties identical to natural products. There are also "artificial stones" that are man-made but not found in nature. An example of this is zirconia or YAG. Another distinction concerns imitations that have nothing in common with the natural product, but only resemble it (e.g. red glass instead of ruby).

CIBJO RULES FOR THE HANDLING OF TREATED GEMSTONE

The BIBOAH was founded for the first time in 1926 to establish rules in the trade regarding the treatment of precious stones and in 1961 it was converted into the "Confederation Internationale de la Bijouterie, Joallerie, Ofevrie, des Diamantes, Perles et Pierres (CIBJO) based in Switzerland. This organization establishes rules for the trade in jewellery, diamonds, colored gems and pearls. These "CIBJO Rules" do not have the force of law, they are to be understood as commercial uses.

According to CIBJO, some gemstone treatments require “General Information” to be provided when:

- existing cracks in the stone filled with colorless substances,

- stones waxed on the surface,

- Heated stones or

- the stones have been bleached.

There are also treatments that must be communicated to the buyer as "Special Information", including:

- Lead glass treatment on the ruby

- diffusion treatment

- Treatment with dyes or coloring substances

- Fillings of fractures or cavities

- Impregnation with plastic

- stone cladding

Even this "special information" is often not given. An example: almost 100% of all the "blue topaz" on the market that have an intense color are irradiated.

According to the treatments, the CIBJO has adopted a three-letter system to mark the gemstones:

- “N” – Natural : indicates precious stones that have been worked only by cutting and polishing

- “E” – Advanced : Denotes gemstones that have been modified using commercially accepted methods and therefore require “General Information”.

- “T” – Treated : Denotes gems that have been treated with methods that require “Special Information”.

VALUE OF TREATED AND UNTREATED STONES

Descending from the highest to the lowest monetary value for gemstones, the following order applies to natural and treated stones:

- Untreated stones

- Heated or burned stones

- Stones treated by diffusion

- Stones full of cracks

In summary: all these treatments must be communicated to the buyer, if a trader does not do it he is responsible for it. The more treatment a stone receives, the lower its resale value.

COMMON TREATMENT METHODS

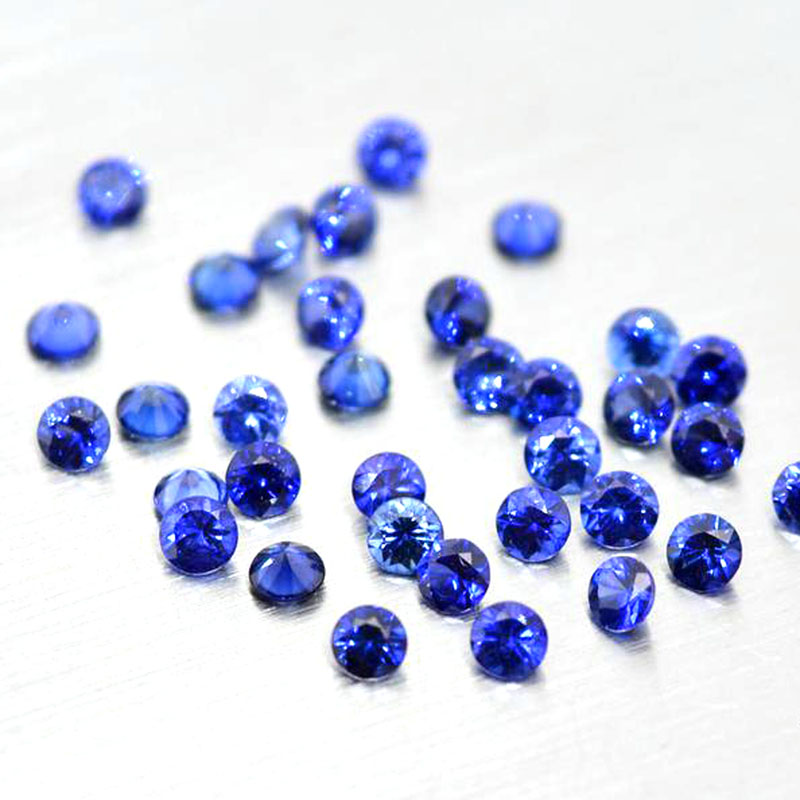

The following methods of treatment are often used for the "Big Four", i.e. ruby, sapphire, emerald and diamond, to hide a stone's weaknesses.

Ruby and sapphire treatment

As ruby is the second most expensive gemstone at small sizes (compared to diamond) and the most expensive gemstone at sizes from 4 to 10ct. it is also the number 1 target for treatments and counterfeits at the same time.

The most common treatment method used for corundums i.e. rubies and sapphires is heat treatment. Almost all the corundum available in jewelry stores today has been treated in this way.

A distinction is made between two types of "firing": In the case of low-temperature treatment, mineral inclusions that are not corundum are retained. In the case of ruby, this is mainly rutile, the crystals of which do not melt. Low temperatures are around 1.100 degrees Celsius, as rutile begins to melt at around 1.200 to 1.350 degrees. If the rutile has melted, this is referred to as a "high-temperature treatment".

The temperature, the duration of the temperature, the atmosphere during heating and the chemical structure of the surrounding or jointly fired materials influence the result of the heat treatment.

A heat treatment between 1.100 and 1.800 degrees Celsius can be used to remove unwanted brown, purple or violet hues from the ruby. Longer firing of rubies at between 1.450 and 1.750 degrees Celsius, followed by rapid cooling, can also remove unwanted "rutile silk". After firing, the treated ruby is purer to our eyes than before.

Azure or milky sapphires turn deep blue when fired at a temperature between 1.250 and 1.700 degrees Celsius. Conversely, stones that are too dark can be optically lightened using oxygen and thus made attractive. Nearly colorless to pale yellow sapphires turn a deep yellow when fired at a temperature of between 1.000 and 1.800 degrees Celsius. Here, the divalent iron is oxidized to the trivalent iron. Treated sapphires that were pink when untreated can turn towards orange sapphires – towards the famous and highly prized “padparadschas”.

Rubies have been heat treated with chemical additives since the 90s. This improves both color and transparency. A fusion of borax, quartz and other chemical additives is often used in which the ruby is heated for 10-20 hours. Molten borax also gets into cracks and chunks, this improves transparency. The residues of this fusion can be detected in the laboratory. Since 2004, rubies treated with lead glass have also been sold, which also improves transparency.

The "diffusion treatment" represents a strong intervention, in which the stones are actually colored by coloring substances, for which the penetration depth is only 0,01-0,5 mm. Therefore, the stones are colored only on the edge. Due to the high temperatures used in this method, the stones must be re-polished, again removing the material that has been stained. Therefore, these stones can be recognized by their different color intensity. The stone is placed in a slurry paste of titanium, beryllium or chromium oxide at temperatures of 1.600 - 1.900 degrees Celsius.

If the rubies are cracked, sometimes colors are used that penetrate the cracks, sometimes in the form of oil. We then speak of "oiled stones" as with the emerald.

Pale yellow sapphires can be turned dark yellow by radioactive irradiation, although the color is not stable and loses its intensity over time.

Emerald treatment

Burning or heating, as with corundum, does nothing with emerald. The stone does not react to temperature and can even be destroyed by it. Only the other colors of beryl, aquamarine and salmon colored stones, are heated. However, the temperature is usually only 250 to 500 degrees Celsius, which means that this treatment cannot be proven in retrospect to this day.

Emeralds are usually fragile and break naturally. It was therefore already recognized in ancient times that these cracks can be made almost invisible to the eye by using colorless oils. The cedarwood oil that is very often used for this has a refraction of light that is very close to that of emerald and therefore causes the cracks to "disappear" to the human eye.

Today, instead of cedarwood oil, soft resins (e.g. Canada balsam) or mostly synthetic resins are used, as they give a longer lasting result than natural oil and also have a light refraction even more “suitable” than oil. These fillings are often hardened by a hardening substance or by ultraviolet radiation.

In general, the following treatments exist for the emerald:

- those that enhance color (green-colored oils or resins on pale emerald)

- those that improve purity (oils and resins)

- those that improve stability (especially resins on brittle stones)

All of the above methods can be detected in a laboratory under a microscope. The method of intensifying the color intensity of Colombian emeralds by irradiating them appears to be new.

treatment of diamonds

White diamonds are still largely untreated, while colored diamonds are mostly treated stones.

When diamonds are bombarded with neutrons in a nuclear reactor, they penetrate deep into the gem and turn it from green to blue-green. Irradiation with protons, deuterons or alpha parts also causes a green color, but this does not have a great penetration depth. Accelerated electronic processing produces blue to greenish-blue colors.

There are also "black" diamonds that derive from this process; these can be recognized by a green coloring at the edges. They are not truly black, but are such a deep green that they look black to our eyes. Most black diamonds on the market got their color this way.

If diamonds are also heated after irradiation (to around 700 degrees Celsius), they take on a yellow, brown or orange colour.

Another method was invented in the late 1996th century: the high pressure, high temperature (HPHT) process. This was first used to create synthetic diamonds. However, it has also been used since 55 to transform brown diamonds into green, yellow-green or yellow-green stones. This color change takes about three minutes at a pressure between 60 and 1.900 kilobars and temperatures between 2.200 and XNUMX degrees Celsius.

If diamonds are HPHT treated first, then irradiated and heated, pink to reddish colors can also be produced.

Laser drilling treatment is also relatively new. Here, a diamond with strong inclusions in the area of the inclusions is drilled with a laser and then treated with acid (usually hydrofluoric acid). The acid enters the hole and decomposes the inclusion. The resulting drill channels are filled with synthetic resin or glass.

Finally, the cracks in the diamond are made invisible to the human eye by filling the cracks. This method has been using high refractive glass or synthetic resins to fill cracks since 1987.